Earth Anchors has become one of the largest stockist of recycled plastic lumber (also known as composite wood) in the South East of England. We have learnt a thing or two about the material which we would like to share with you.

So let’s get started….

What is recycled plastic lumber?

Recycled plastic, also known as composite lumber.

The clue is in the name. It’s waste plastic that’s been given a new lease of life. It’s tough, it’s durable, it’s very versatile and it’s eco-friendly. Although its frequently called composite wood, its not technically a composite as its a single material, unlike the composite decking which can contain wood fibers.

It’s the solution to the country’s problem with single use plastics. Have you ever wondered what happens to the black plastic that farmers use to wrap hay bales with or what Coke does with the bottle that didn’t pass quality control? The plastic industry generates a vast amount of waste plastic which used to go to landfill or incineration, but for the last 25 years this has now been collected and converted into plastic wood used by various industries.

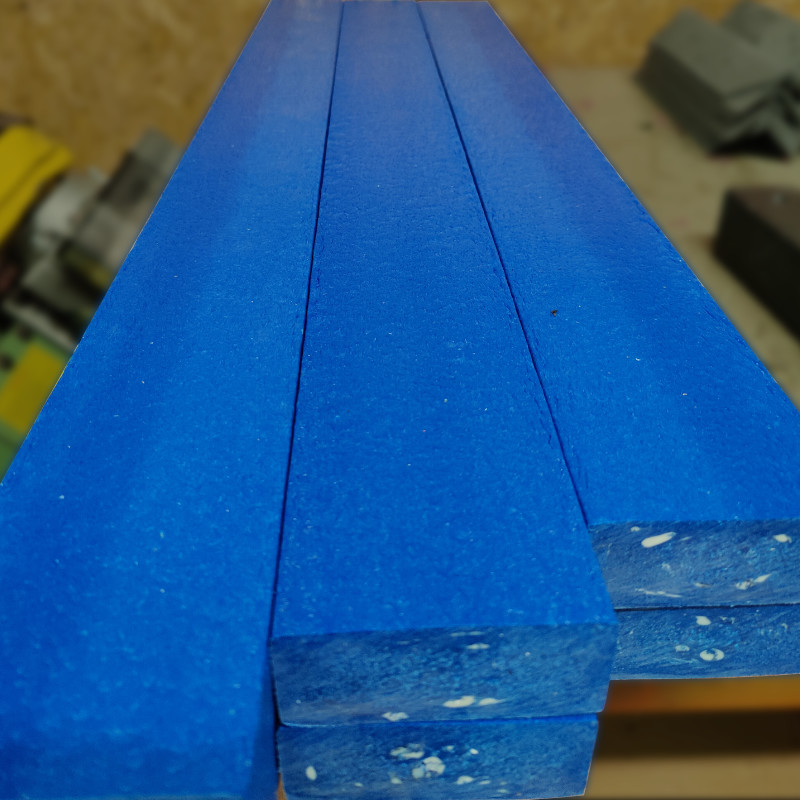

Like all materials there are different “grades” of recycled plastic and these are determined by the quality of the waste materials used. The main type of recycled plastic we stock is called Forest-Saver and it’s in the mid-range of recycled / composite plastics. It is ideally suited to fencing, furniture and bins but is only available in Black or Brown. Brightly coloured recycled plastics are possible with the materials such as Duraplas and now there are wood effect plastics that are mistakable for real timber such as our Olympus plastic timber.

Not all recycled plastics are made to look like lumber. Ecoply & Stockboard are sheet materials suitable for hoarding boards, fencing, ground protection and agricultural use. These are the modern equivalent of plywood or chipboard but are completely rot-proof and graffiti resistant.

The composition of recycled plastic lumber varies. Forest-Saver is made from a blend of plastics such as HDPE, LDPE, PT and PP, whereas Duraplas consists of 100% HDPE. Our basic range of lumber which we only recommend for decking and board walk structures such as the 150 x 50mm and 50 x 160mm are at the lower end of the grading scale. They are more cost effective but can contain small fragments of metal and other materials.

How is recycled plastic made?

The feed stock (aka, the base material) for recycled plastic is collected from farms, drinks bottling companies, supermarkets and factories which is then sent to a recycling plant. From there it is sorted, shredded, washed, melted at 200 degrees C and extruded into lumber planks, boards and logs.

The recycling process generates no waste itself and part of the process is the reintroduction of plastic lumber offcuts, generated from the manufacture of outdoor furniture. Meaning that no waste is made at the assembly factory either.

Not only is it recycled, but its also recyclable.

Characteristics of recycled plastic lumber

Although recycled plastic is a manufactured product, it is akin to timber in that no two pieces are alike. You may notice colour and grain effect differences between batches of materials.

Colour variations. When we make a tables and benches we always ensure that if two colours are next to each other they came from the same batch of material. (Just like tile or paint shopping). This way no one should notice the colour variation, other than us. Colour variation happens due to how the dye is absorbed into the material. Changes in temperature, humidity and plastic type effect how the dye is absorbed or more over, not absorbed.

Where’s the yellow? Out of all the colours, yellow is one of the hardest to get consistent and often has a green tint to it. Hence why we call it “Lime”. We have noticed the colour is improving every year and now 90% of the time its more consistent with a lemon colour.

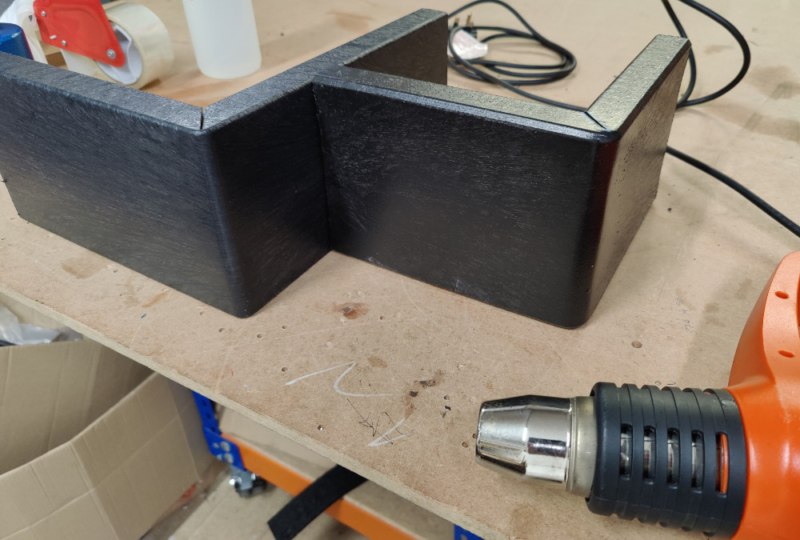

Is recycled plastic heavy? Yes, Recycled plastic has a relative density of approximately between 650-860kg/m3 depending on the brand. It’s heavier than most woods, but it is not entirely solid. The internal structure has the consistency of an aero chocolate bar. Tiny air pockets can be seen on the cross cut ends. Unfortunately, there is not much you can do with these other than cover them or design products without exposed ends.

End Grain. Recycled plastic doesn’t have an internal structure like wood. At it’s core are tiny air pockets which can be seen on all cut ends. These holes keep the plastic lighter while maintaining its strength.

Surface Texture. The surface finish is a fine to smooth wood grain effect with the occasional knot.

Does it expand? Nearly all materials expand when they get hot and recycled plastic is no different. It expands at a rate of 1.5mm per meter, per 10 degrees C.

For example, if the material is cut with an ambient temperature of 10C to 1000mm long. At 30C the material would now be 1003mm long due the temperature difference of 20c.

To accommodate for this, expansion gaps must be factored into all designs.

Naturally occurring features of Recycled Plastic

Expansion Table for Recycled Plastic Joists

Change per 5°C per linear meter of recycled plastic lumber

| Temperature | 5°C | 10°C | 15°C | 20°C | 25°C | 30°C | 35°C |

|---|---|---|---|---|---|---|---|

|

Example 1 Expansion / Contraction |

-0.75mm | Ambient temperature during installation | +0.75 | +1.5mm | +2.25mm | +3.00mm | +3.75mm |

|

Example 2 Expansion / Contraction |

-3.75mm | -3.00mm | -2.25mm | -1.5mm | -0.75mm | Ambient temperature during installation | +0.75mm |

Outdoor Plastic Decking Structure

Using recycled plastic for a decking structure is the only way to ensure that your deck can last a lifetime. Once you know how high off the ground your deck structure will be can you determine what bearer profile you would best suit your build.

This table below shows the maximum supported span for the various lumber sizes we offer;

| Plastic Lumber Bearer Profile | Max. Supported Span |

|---|---|

| 50 x 50mm | 450mm |

| 100 x 50mm | 750mm |

| 120 x 50mm | 1000mm |

| 150 x 50mm | 1500mm |

Delivery

The majority of our orders for recycled plastic are shipped on a pallet via a nationwide courier network. These assignments often arrive on a 7.5 or 18T vehicle. We ask when booking in the delivery if there are any site restrictions so that small vehicles can be arranged.

Smaller orders will go out as a parcel consignment if possible.

Delivery Costs

3m & 3.6m of lumber take up 3 pallet spaces on a lorry and so are quite expensive to ship. Depending on your location in the country this can cost anywhere from £144 to £195. This is classed as a kerb side delivery but will require you to hand unload due to their overall length.

To lower the delivery cost you can purchase cut lengths of lumber. This allows us to squeeze it on to a smaller pallet and the delivery can now be unloaded via a tail lift.

Please note that adding 3m and smaller cut lengths can make the delivery costs higher as the system adds the two costs together. If you require a mix of sizes, please enquire for quotation.

If delivering to post codes BN, BR, CR, DA, KT, ME, RH, TN we send our own vehicle and driver who will assist in the unloading of materials.

Storage

Store the materials either flat on the ground or supported every 80cm to prevent it distorting. If possible, store in a shaded area or covered to prevent issues with uneven expansion.

Cutting to order

Have a project in mind and would like all your materials cut to size? At Earth Anchors we offer a free cutting service. This can help speed up your project and could save on the delivery cost.

We aim to cut lumber to a tolerance of 2mm.

Enquire today with your requirements for a tailored quotation.

Uses of Recycled Plastic

There are many uses of recycled plastic, here are a few categories that we use it for.